Powering innovative manufacturing that transcends convention are advanced technology and the equipment that supports it. At Make Start, we are equipped with cutting-edge machinery, including 5-axis machining centers, to meet the needs for increasingly complex and sophisticated processing. By maintaining a fully integrated in-house processing system, we resolve various challenges speedily and flexibly, realizing high-quality and high-efficiency manufacturing.

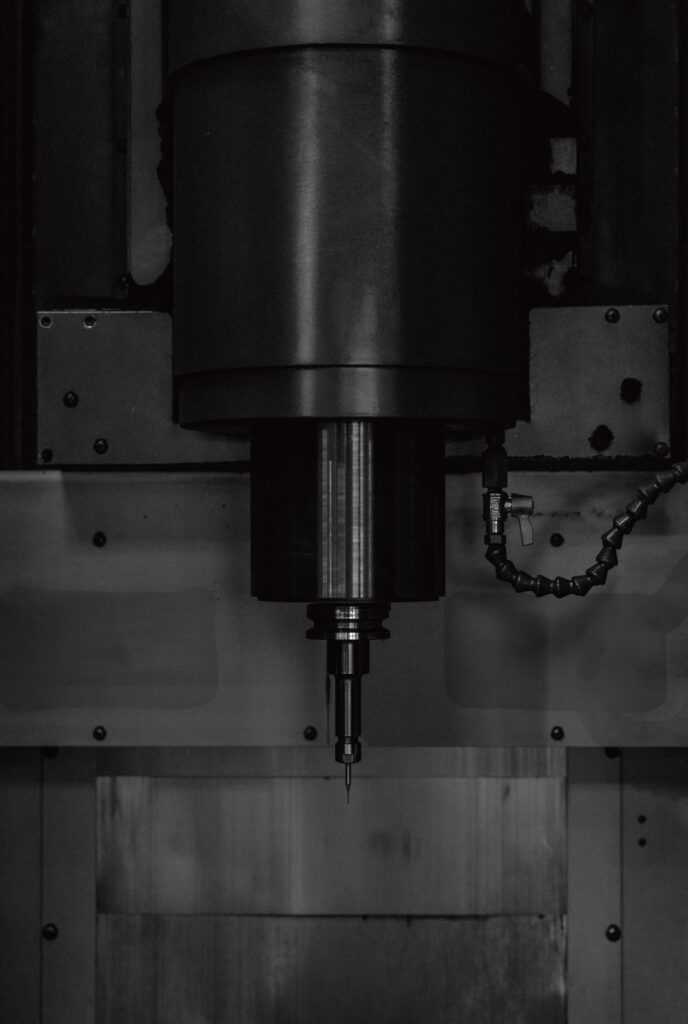

We have introduced 5-axis machining centers that enable the processing of high-precision and highly difficult shapes. A single machine can handle complex undercuts and multi-sided machining, reducing the number of setups to achieve both precision and speed. We realize efficient 5-axis programming through integration with our in-house CAM systems.

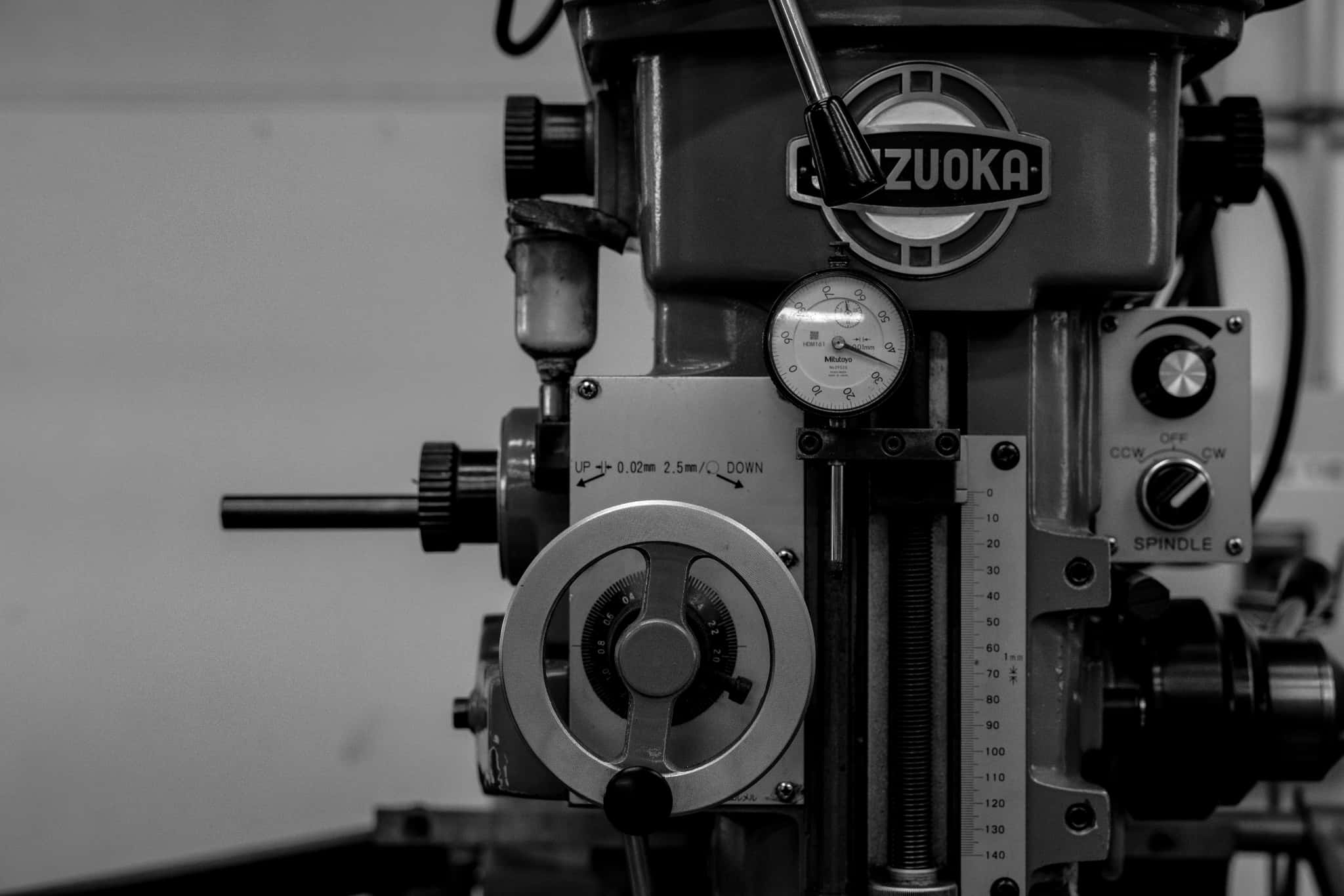

Possessing numerous 3-axis and multi-axis machining centers, we handle cutting processes for diverse materials such as aluminum and steel. By fusing the skills of expert machining technicians with digital technology-driven setup procedures, we achieve stable machining accuracy and flexible responsiveness.

These cutting machines remove material from metal or resin using rotary tools. Capable of diverse operations such as face milling, grooving, and end milling, they achieve high precision and freedom through manual control by skilled experts. At Make Start, our certified “Contemporary Master Craftsmen” demonstrate their skills to the fullest here.

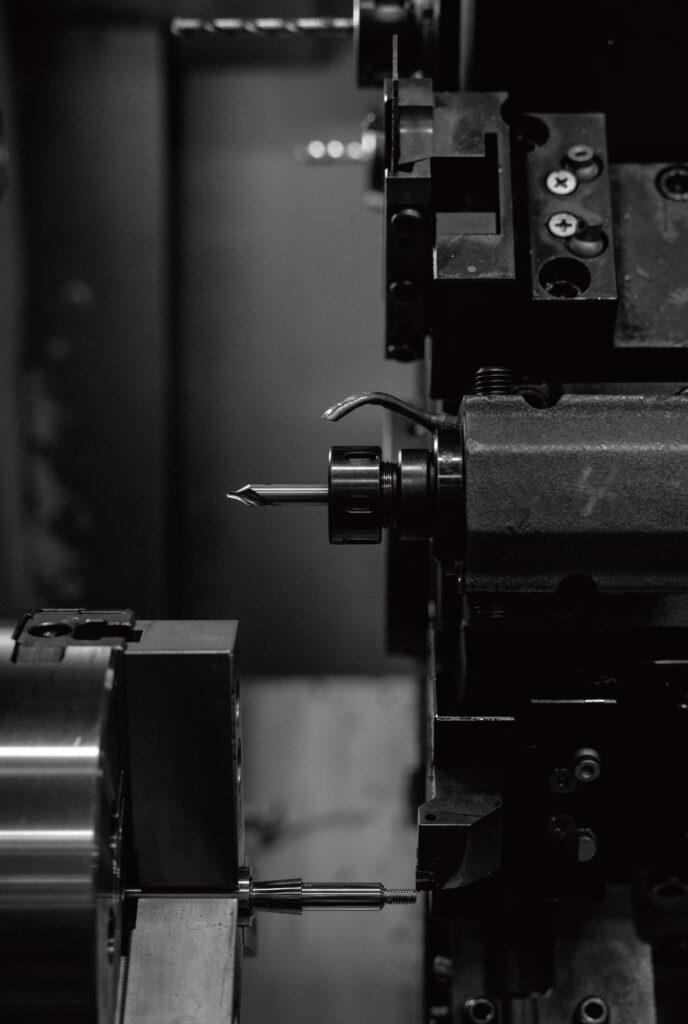

We have introduced CNC lathes for high-precision turning of round parts. Handling a wide range of items from jig components to complex shaft shapes, we have established an integrated in-house processing system.

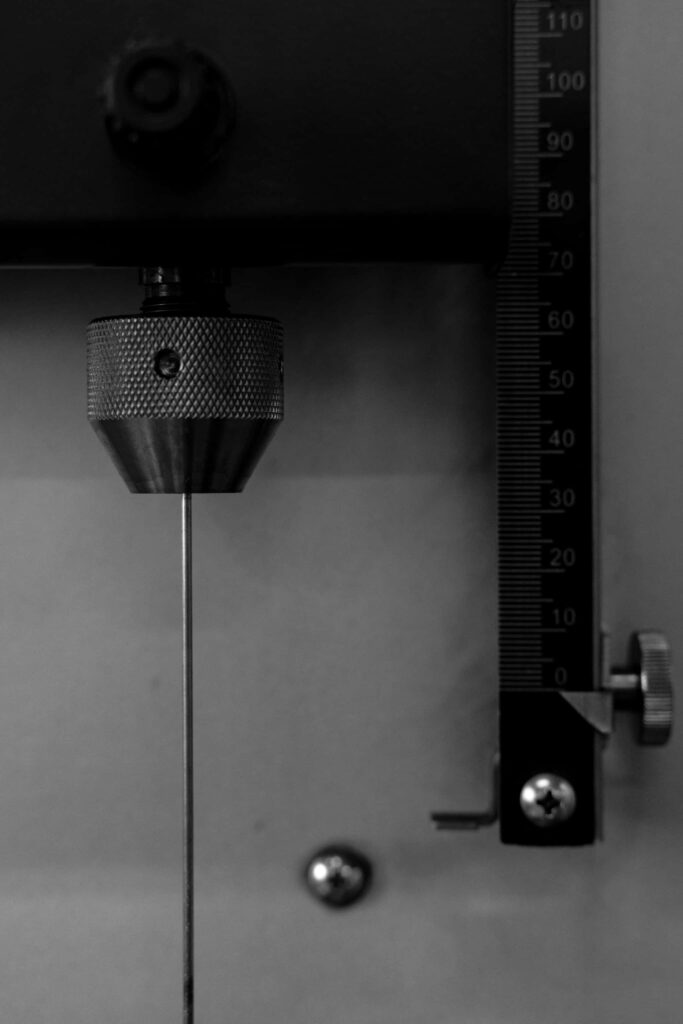

We have introduced electrical discharge machines specialized for small-hole drilling, such as creating air vents in molds or holes in electrodes. Stable drilling into high-hardness materials is possible, and we are confident in maintaining precision after processing. Furthermore, we support small-diameter water cooling hole machining and have a system to respond quickly to urgent additional processing requests.

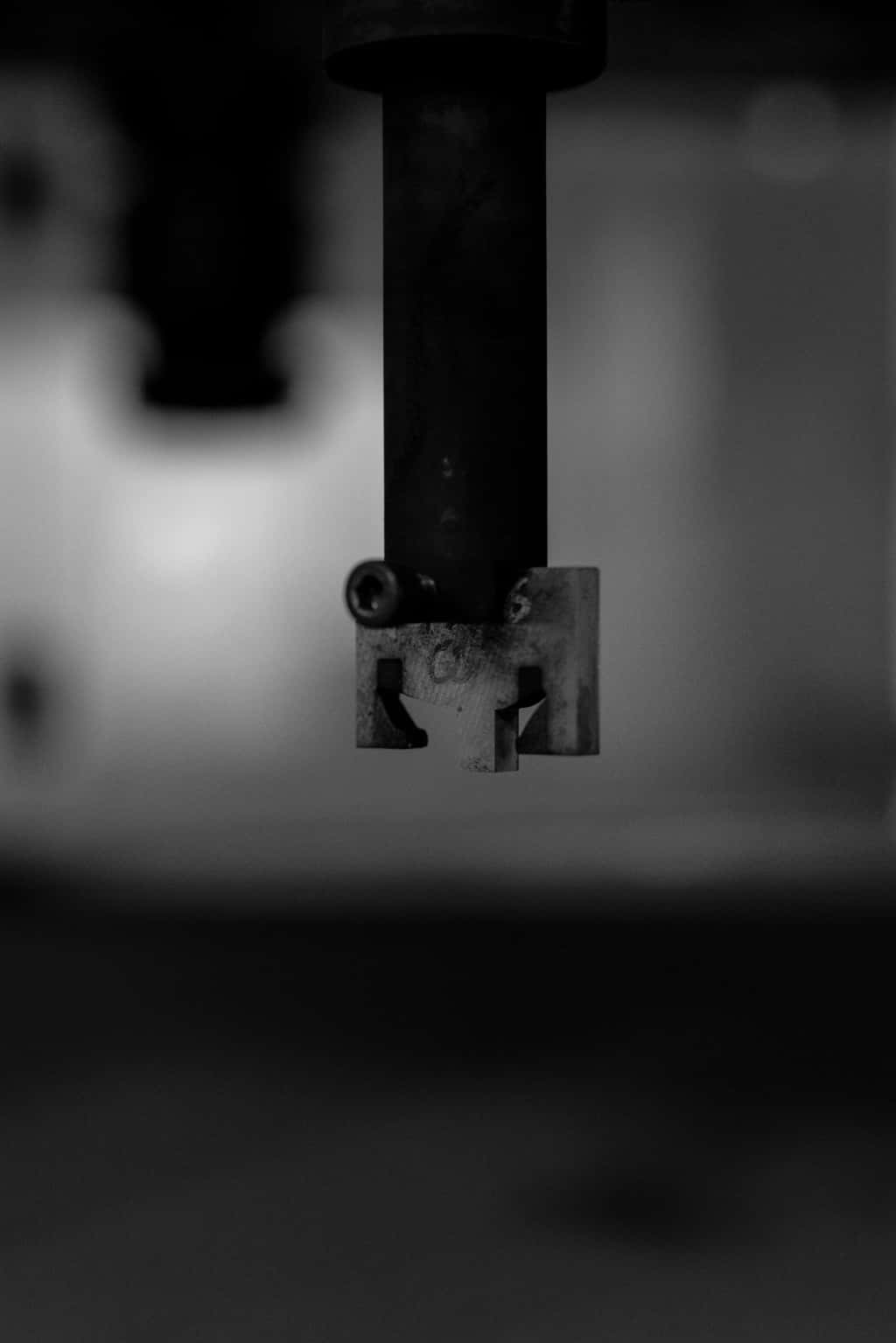

This equipment performs minute machining on metals using spark discharges between an electrode and the workpiece. Capable of handling shapes difficult for standard machining—such as complex concave shapes, deep grooves, and undercuts—it is an indispensable precision machine for manufacturing resin and rubber molds.

This equipment joins metals at temperatures lower than usual. It causes minimal heat distortion or damage to the material, making it suitable for joining precision parts and dissimilar metals.

We have introduced dedicated graphite machining centers for processing graphite electrodes. In an environment with thorough dust control measures, we finish even minute and complex shapes with high precision. As a process directly linked to EDM, we ensure smooth in-house coordination, contributing to shorter manufacturing lead times.

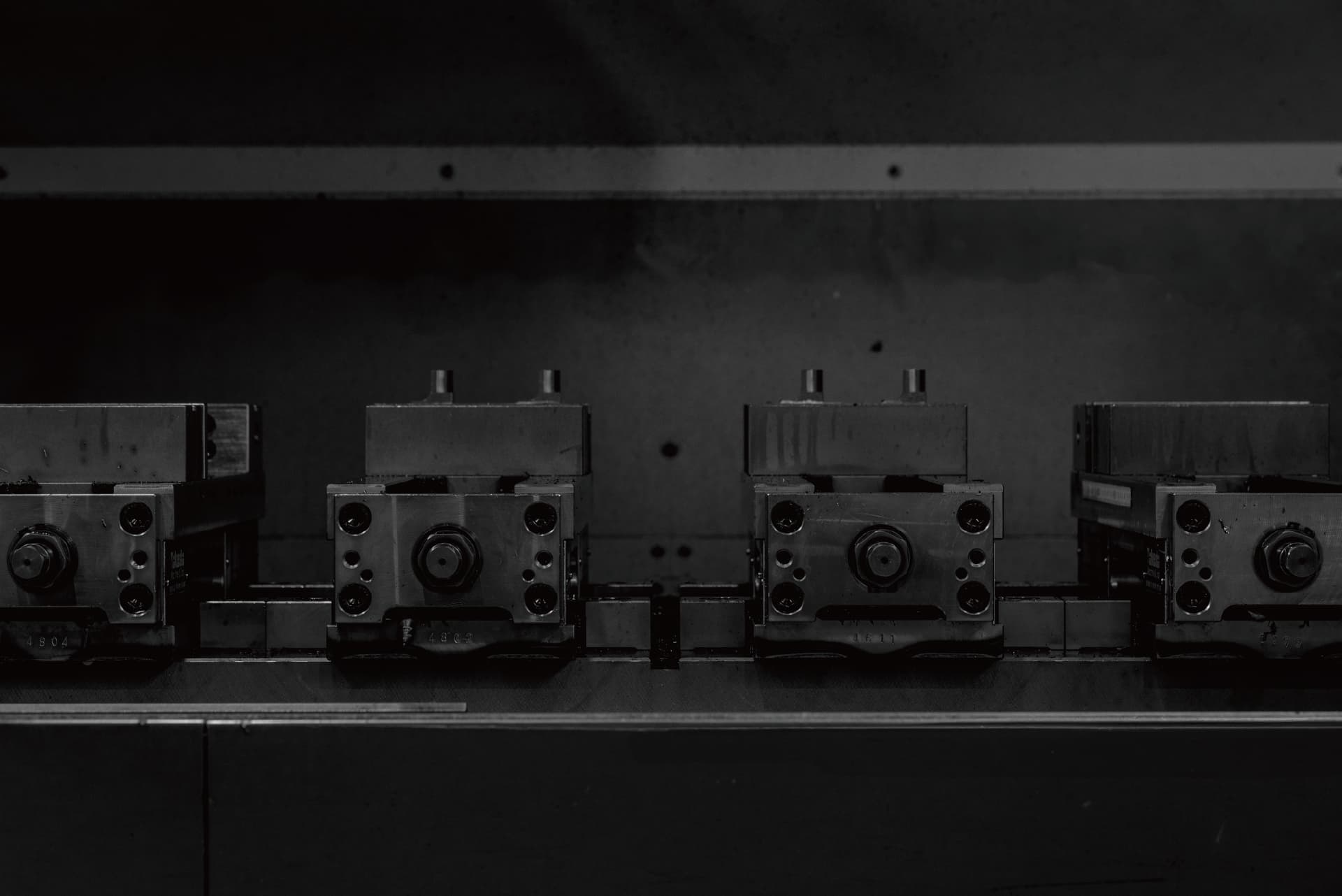

Specialized press machines used for fitting molds and checking molding conditions. The 150-ton machine is used for large resin molding dies, while the 20-ton machine is used for adjusting precision rubber molds. They play a crucial role in the final adjustment process to enhance mold finishing accuracy.

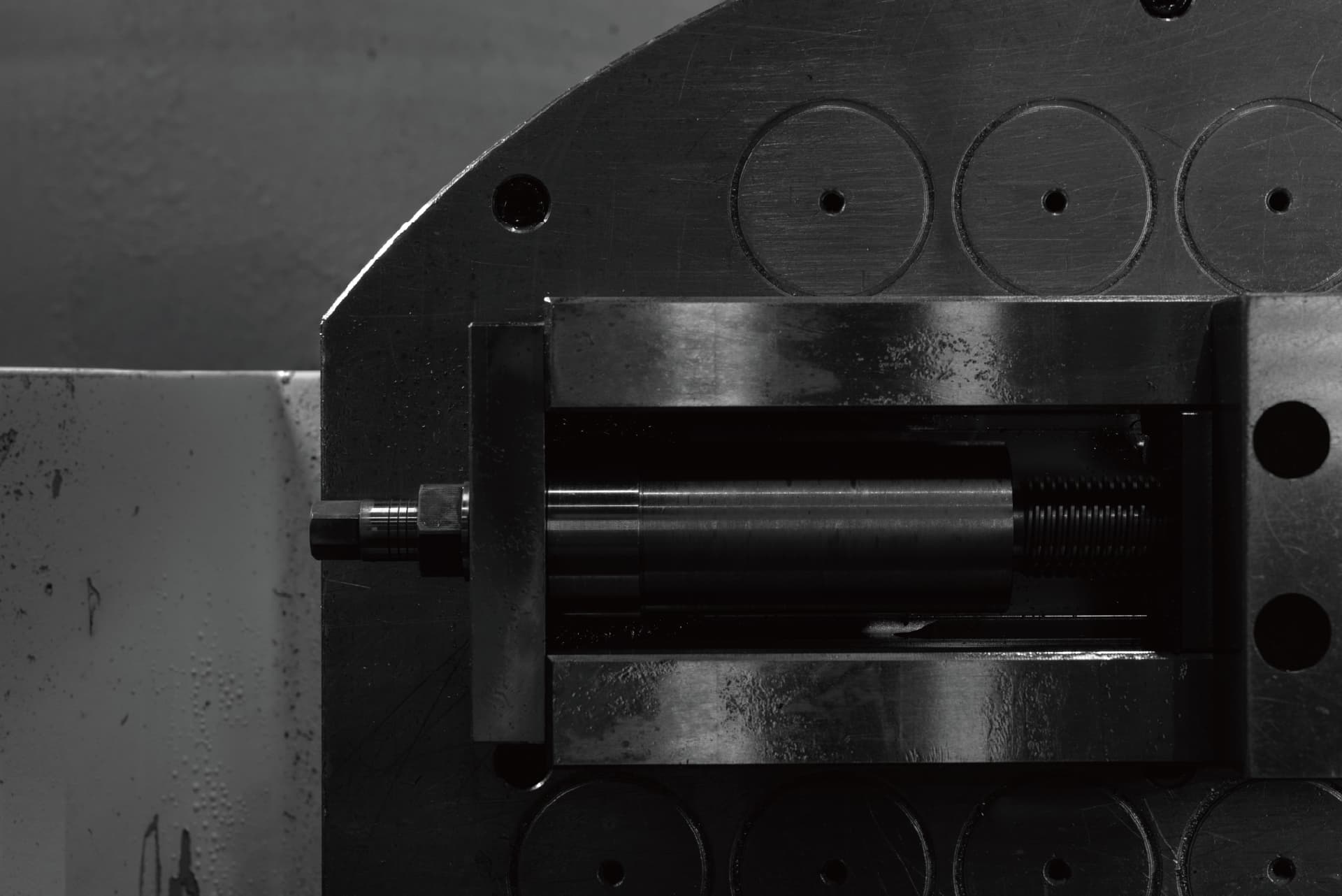

Utilizing Wire-cut EDM, which is essential for processing precision parts, we achieve machining accuracy on the micron level. We respond flexibly to high-hardness materials and complex shapes. Through coordination with our internal EDM processes, we offer consistent support from electrode fabrication to finish machining.

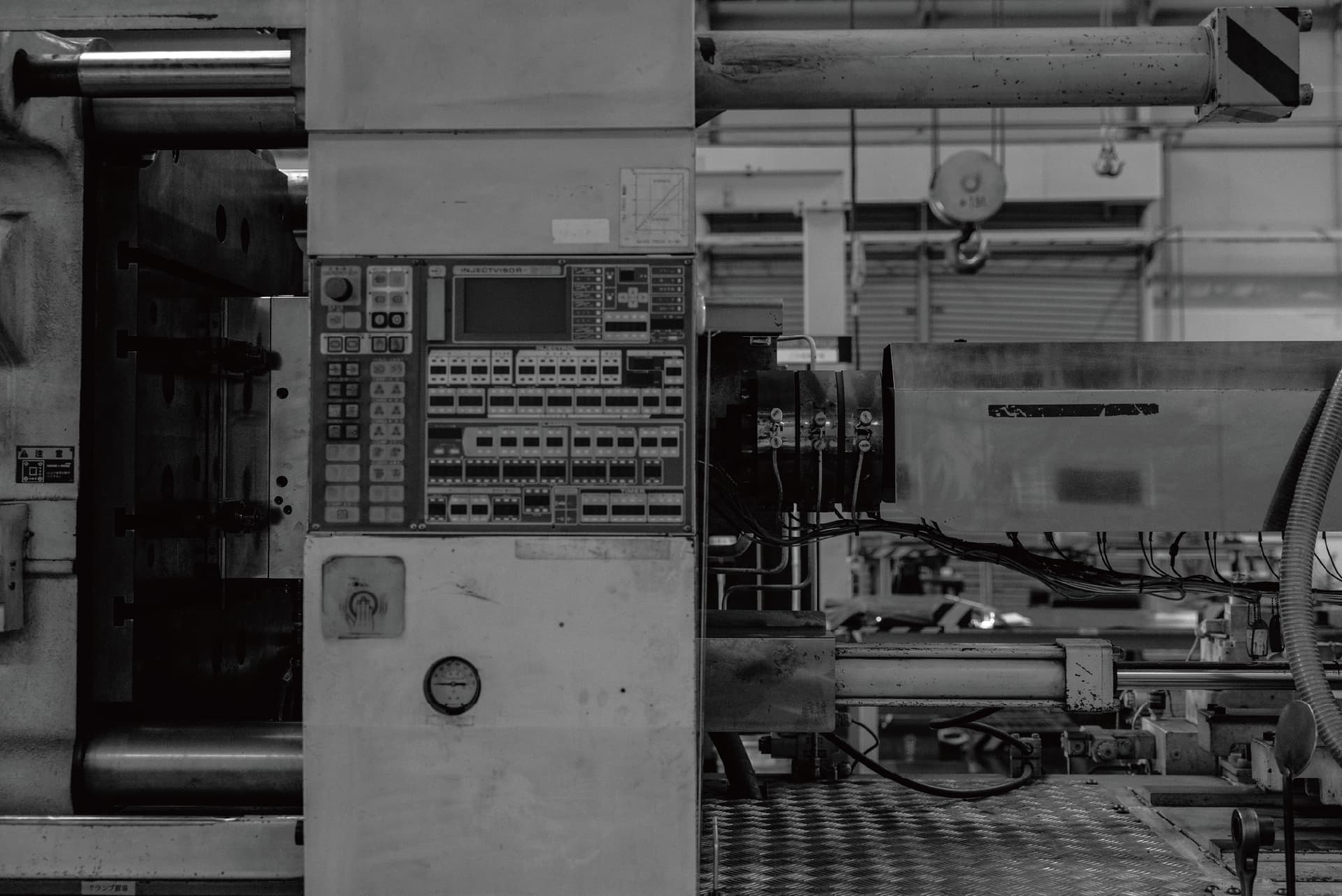

An injection molding machine with a clamping force of 350 tons, used for trials of QTR types and resin injection molding dies. It is utilized as vital equipment to check the molding state and product shape before delivery, performing final verifications of mold perfection and molding conditions.

Finishing equipment that precisely grinds the surface of parts after machining to improve surface roughness and dimensional accuracy. Used particularly in the final stage for high-precision mold parts, it handles critical finishing processes that determine product quality.