Solving challenges through manufacturing. With this passion as our starting point, Make Start has expanded the high-precision processing technology and creativity we cultivated in the fields of automotive parts and rubber molds into every realm. Our five business lines will give shape to new value for the future. From zero-tolerance molds that enable a comfortable car life, to medical devices that protect lives while reflecting the realities of the clinical front line, to tools that meet the expectations of professionals and players. What all of our businesses have in common is manufacturing that stays close to the voices of the people who use our products and captures the true essence of what is needed. With innovation, playfulness, and kindness toward people at their core, Make Start’s five business domains will continue to shape new value for the future.

We specialize in molding dies for rubber, a material with complex physical properties. We boast a top-class track record in Japan particularly for automotive weatherstrip molds, and our products are adopted by many domestic automakers. At our five self-owned overseas bases, we train engineers to provide “Japan Quality” products globally. We also handle plastic (resin) injection molds and can perform repairs and maintenance on molds manufactured by other companies.

We entered the healthcare field driven by the problem-solving mindset of our President, who is an active physician with deep knowledge of medical settings. Our first product was “TOUCH WRAP,” addressing keyboards that are difficult to disinfect. Subsequently, we jointly developed “FORUshield,” a radiation protection shield to reduce exposure during catheter surgeries, with Teikyo University. This product has achieved patent acquisition and received an award for industry-academia collaboration.

Based on technology cultivated in mold manufacturing, we developed the “MUQU” golf club brand. Through precision milling technology that carves from solid iron, we have realized a structural beauty akin to industrial art and an other-dimensional precision of 0.01mm. With creativity unique to a company that knows iron inside out, we offer specifications allowing a choice between three types of steel. The product line has expanded to irons, wedges, putters, and practice balls, captivating golfers both in Japan and abroad.

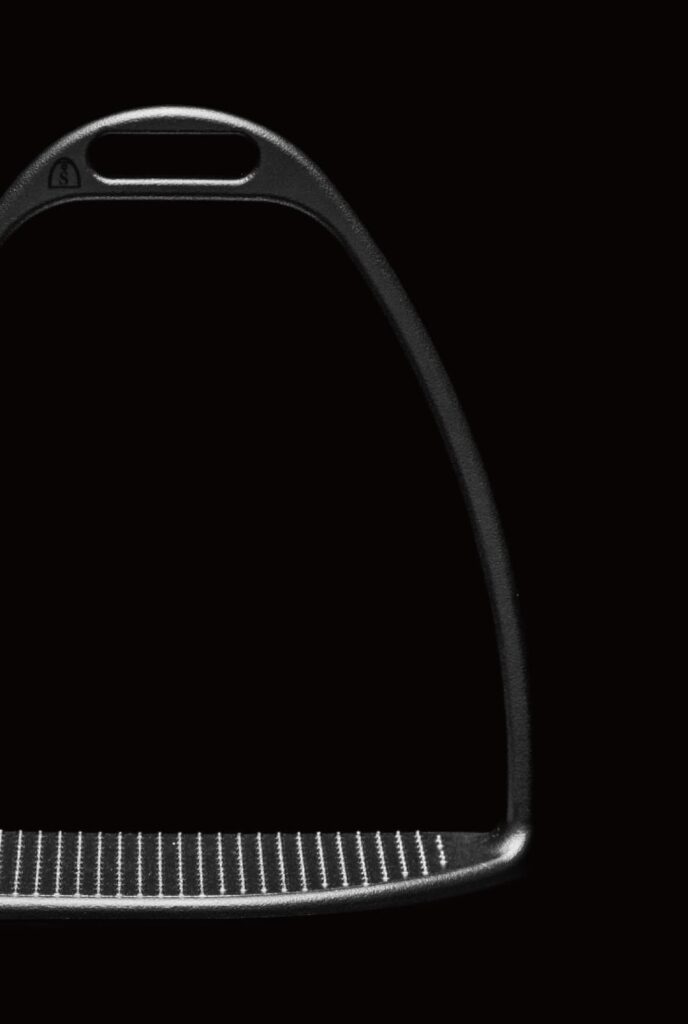

Our equestrian equipment business began with a single remark from Japan’s top jockey, Yutaka Take: “There are no stirrups that fit my feet.” At the time, there were no stirrup manufacturers in Japan. Leveraging our mold milling technology, we developed the first Japanese-made stirrup, “ABUMI,” together with Jockey Take. He has achieved numerous victories in domestic and international races, including the Prix de l’Arc de Triomphe, using these stirrups. Our “Made in Japan” stirrups are highly acclaimed overseas.

Splitting firewood and hammering pegs at camp can be a burden for women and children. Addressing this, we applied the mechanics of a cold chisel to develop “Senpo,” a camp-specific wedge that splits wood safely with light force, and “Tezuchi,” a specialized hammer fusing the craftsmanship of swordsmithing, woodworking, and metalworking. The brand name “Owari no Outsuke” derives from Oda Nobunaga, a historical figure associated with our home of Kiyosu, symbolizing our stance of manufacturing that strikes at the essence of things.